From Rough to Refined: Boosting Efficiency with CBN Wheel Truing Equipment and CNC Dressing Machines

Surface polish, dimensional accuracy, and tool lifetime are non-negotiable in the precision manufacturing sector. Industries are looking towards increasingly complex solutions to satisfy the needs of consistent surface grinding and high-performance tooling. Two of the most groundbreaking technologies changing the grinding scene are CNC wheel dressing machines and CBN wheel truing equipment. These instruments have become crucial resources in many industries as the need for closer tolerances and more production increases.

Why Is CBN Wheel Truing Equipment Unavoidable?

Widely known for their longevity, heat resistance, and cutting power are Cubic Boron Nitride (CBN) grinding wheels. But keeping their form and efficiency calls for sophisticated training techniques. When it comes to restoring the profile of the wheel and removing anomalies, CBN wheel truing technology provides unrivaled precision. The fast, high-precision needs of contemporary production are just too much for conventional dressing techniques.

Using certain tools to true CBN wheels not only increases their life but also guarantees more consistent grinding outcomes. Less downtime, improved tool life, and less waste help operators—important measures in competitive sectors, including aerospace, automotive, and precision machining.

CNC Wheel Dressing Machines: Where Automation Meets Precision

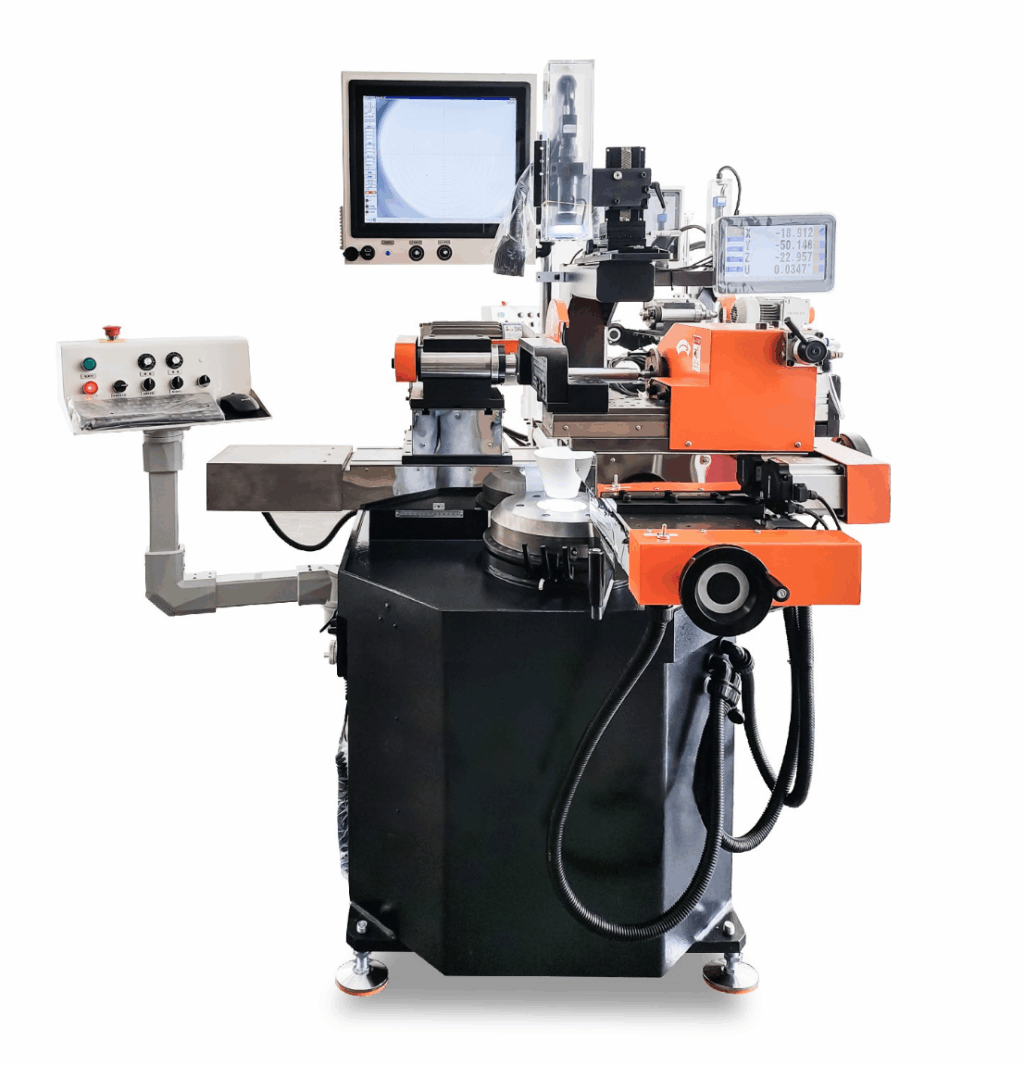

CNC wheel dressing devices have become standard in advanced grinding processes as a result of the demand for precise, programmed control over wheel profiles. These machines provide constant performance with the least manual involvement by means of software, hence enabling users to specify complex wheel forms and dressing cycles.

Unlike manual or semi-automatic methods, CNC wheel dressing machines guarantee that every dressing cycle is done with accuracy. The automation increases the general efficiency of grinding systems, quickens dressing times, and lowers human error. Whether for CBN wheels, resin-bonded, or vitrified, these machines guarantee the utmost repeatability.

The Interaction of Truing and Dressing

Though they have somewhat varied goals, CBN wheel truing tools and CNC wheel dressing machines cooperate to preserve grinding wheel performance. While dressing exposes fresh cutting edges to sharpen the abrasive surface, truing fixes wheel form and concentricity. Many processes start with truing; then, exact dressing gets the wheel ready for premium cutting.

Manufacturers can maximize the cutting performance and geometry of the grinding wheel by combining both procedures with modern tools. Industries like mold building, turbine manufacture, and medical device production need precision surface finishes, so this synergy is very vital.

Increasing Output with Modern Grinding Solutions

Using CNC wheel dressing machines and CBN wheel truing tools greatly improves manufacturing cycles. By minimizing tooling costs and increasing general production, these methods cut the need for wheel replacements and regrinding. Furthermore, automated truing and dressing let producers manage complicated components with fewer flaws and closer deadlines.

Modern production values time highly; therefore, any procedure that saves time without compromising quality merits the expenditure. These devices not only reduce manual effort but also offer predictive maintenance analysis that helps prevent unanticipated downtimes.

Precision tools will determine grinding’s future.

Reducing waste and lengthening tool life is more crucial than ever as businesses become more and more focused on sustainability. CNC wheel dressing machines and CBN wheel truing tools help to achieve these objectives by maintaining grinding processes lean, efficient, and repeatable. Their inclusion into smart production systems is paving the path for Industry 4.0 preparedness.

These technologies also offer adaptability for multi-axis operations, custom profile grinding, and adaptive controls. Precision grinding technology will be absolutely important in providing consistent, scalable, and high-quality output as manufacturers strive to remain competitive all over.

Selecting the Appropriate Tools for Your Business

The kind of grinding wheel, necessary tolerances, and production levels all influence choosing the perfect truing and dressing solutions. Although CNC wheel dressing machines are vital for automated processes demanding consistent outcomes and sophisticated profiling, CBN wheel truing equipment is most appropriate for high-precision and high-hardness applications.

Conclusion

Success is evaluated in microns in the industrial sector of today, which is competitive. Including CNC wheel dressing machines and CBN wheel truing tools in grinding processes has evolved beyond a technological improvement to become a strategic need. These instruments are opening new levels of performance for manufacturers globally with more accuracy, efficiency, and reproducibility. Visit proemachinery.com and start your journey towards precise perfection to investigate sophisticated grinding solutions customized to your requirements.